UN ECE R90

The UN ECE-R90 is a European regulation stating that every replacement for brake friction, -rotors and -drums need to be within specified tolerance against the Genuine part (OEM/OES) of the part that it is to be replaced.

Brake pads

ECE R90 certification testing for passenger car brake pads or shoes is conducted entirely on the vehicle. With an outstanding availability of cars, light trucks, and crossovers and SUVs, we can test almost any part number. Our extensive application database enables us to analyze other WVA numbers for inclusion on the certificate, covering a wider range of part numbers with fewer tests. Commercial vehicle brake pads are certified by dynamometer testing, available at our laboratory in Detroit.

Brake discs

As indicated, replacement brake discs for passenger cars registered after November, 2016 require R90 certification, while discs for commercial vehicles have been required for vehicles registered after November, 2014. Commercial vehicle discs require only dynamometer testing for approval, while passenger car discs are subject to dynamometer testing as well as a confirming road-test (one test per disc ‘type’).

Brake lining

Brake linings or blocks for commercial vehicles need to have ECE R90 certificates when selling within the European Union; other territories such as Egypt, Malaysia and Saudi Arabia are also adopting the R90 regulation. Brake lining certification is accomplished by dynamometer testing, several of which are available in our laboratory in Detroit.

Brake drums

Brake drums for both passenger cars and heavy duty trucks and buses require ECE R90 certification for vehicles with a registration date of November, 2016 and later. Like brake discs, commercial vehicle drums require only dynamometer testing for approval, while those for passenger cars are subject to dynamometer testing as well as a confirming road-test (one test per drum ‘type’).

R90 is required for all brake pads, lining, rotors and drums throughout the European Union and in non-European countries that have adopted ECE Regulations, such as Egypt, Malaysia, UAE, South Africa and New Zealand.

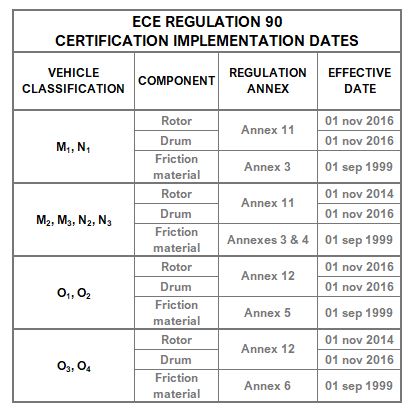

The table below summarizes the effective dates per component and vehicle category for which UN ECE-R90 was implemented:

ECE REGULATION 90 CERTIFICATION IMPLEMENTATION DATES |

|||

| VEHICLE CLASSIFICATION | COMPONENT | REGULATION ANNEX | EFFECTIVE DATE |

| M1, N1 | Rotor | Annex 11 | 01 Nov 2016 |

| Drum | 01 Nov 2016 | ||

| Friction material | Annex 3 | 01 Sept 1999 | |

| M2, M3, N2, N3 | Rotor | Annex 11 | 01 Nov 2014 |

| Drum | 01 Nov 2016 | ||

| Friction material | Annexes 3 & 4 | 01 Sept 1999 | |

| O1, O2 | Rotor | Annex 12 | 01 Nov 2016 |

| Drum | 01 Nov 2016 | ||

| Friction material | Annex 5 | 01 Sept 1999 | |

| O3, O4 | Rotor | Annex 12 | 01 Nov 2014 |

| Drum | 01 Nov 2016 | ||

| Friction material | Annex 6 | 01 Sept 1999 | |

This means that vehicles with a whole vehicle type approval e.g. E13 from before these dates do not necessarily need to be R90 certified, but still can be certified to make sure quality standards are met. The description of testing regulations can be found here.

The UNECE updates the UN-ECE-R90 regular reguarly. Click here for the latest revisions on the UNECE website.

COP CERTIFICATES

The COP Initial assessment is required to show the certification providing institute that manufacturers can:

Maintain a consistent quality level for their R90 certified products.

Describe the testing process and testing environment of their quality inspections.

Describe the acceptance range of their quality standards.

Have procedures in place for how to react on quality fluctuations .

Stay informed about possible amendments in ECE-R90 regulations.

Have a procedure on how to implement R90 amendments into their production control plan.

Download here:

UN ECE R90 FAQ

ECE-R90 is a European regulation stating that every replacement for brake friction, -rotors and -drums need to be within specified tolerance against the Genuine part (OEM/OES) of the part that it is replacing.

R90 is required for all replacement brake pads, lining, rotors and drums.

ECE-R90 is required throughout the European Union and in non-European countries that have adopted ECE Regulations, such as Egypt, Malaysia, UAE, Colombia, South Africa and New Zealand.

No. It is possible to create a group/family of products that can be issued under one certificate. Depending several criteria, we group parts together on factors like:

- Diameter for rotors and drums

- Thickness for rotors

- Material for lining, pads, drums and rotors

- Surface treatment for rotors

- Backing plate design for pads

- Friction design for pads

- Etc.

If a family or group is determined, the “Worst Case vehicle” is selected which is the application used to test the item that needs R90 certification.

The worst case means one specific article number from a R90 family that will be used under a vehicle that has the highest speed/weight ratio of that group.

No. It means that we can analyses the next worst case from that group and exclude the initial worst case from the family. Meaning that the part that did not meet the R90 standards will be excluded from the group. The 2nd worst case should be determined and considered to represent the group.

You can certify them as long as they do not become the worst case and validate of vehicle data of that specific item is available. R90 testing is a comparison to the OE product. Car manufacturers are obliged to offer Genuine parts for 10 years. In some cases, the OE parts are no longer available to run the test with.

We will analyze your drawings and criteria to determine if it can be added to an existing certificate. If it fits the criteria and your new product is not the worst case, it can be added with an Extension certificate.

If your new part number is the worst case, your part number needs to be tested.

We need 6 samples of each WC number for rotors.

We need 1 vehicle sets for friction for PC & CV

We do need additional samples if you require us to run Shear, Compressibility, Metallurgical testing/ Chemical composition and Friction behavior testing.

No. Once a product is tested, manufacturers should have their production process certified and implement CoP related testing periodically. The frequency/sample rate of these tests should be described in the quality manual of the factory holding the CoP certificate.

These are tests that you have to sample in a frequency as described in the quality manual of the factory holding the CoP certificate. These tests contain, Shear Strength, Compressibility and Chemical Composition test.

ISO 6312:2010 specifies a method for measuring the strength of the bond connection between the lining material and the carrier in disc brake pad and drum brake shoe assemblies (shear strength). ISO 6312:2010 is applicable to assemblies that are integrally moulded, bonded or that use mechanical retention systems (MRS) of both types used for brakes on road vehicles. https://www.iso.org/standard/46272.html

This International Standard specifies a method for test and measurement of the compressive displacement of brake linings or brake pad assemblies due to loading and temperature. It also provides a test method to assess lining thermal swell and growth.

This International Standard applies to disc brake pad assemblies or coupon samples cut from the friction material. https://www.iso.org/obp/ui/#iso:std:iso:6310:ed-3:v1:en

ISO 6508-1:2015 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic materials and is applicable to stationary and portable hardness testing machines.

https://www.iso.org/standard/59686.html

ISO 26867:2009 describes a test procedure for assessing the influence of pressure, temperature, and linear speed on the coefficient of friction of a given friction material in combination with a specific mating component (rotor or drum). https://www.iso.org/standard/43848.html

ECE-R90 consists out of two parts:

- Your tested product must meet the R90 standards

- Your future products must also meet the R90 standards

This means that it’s not only products that need to be R90 certified but the factory who produce R90 certified products need to behave in a certain way to guarantee that all products produced in the past, present and future have the same standard. For that reason, a factory needs to have a Conformity of Production (CoP) plan implemented in their quality manual. If a factory does not have a CoP, their product cannot be ECE-R90 certified.

Every factory who produces R90 certified products need to behave in a certain way to guarantee that all products produced in the past, present and future have the same standard. For that reason, a factory needs to have a Conformity of Production (CoP) plan implemented in their quality manual.

We advise to test your products and apply for CoP simultaneously.

The UNECE updates the UN-ECE-R90 regular reguarly. Click here for the latest revision on the UNECE website.