From: The Brake Report

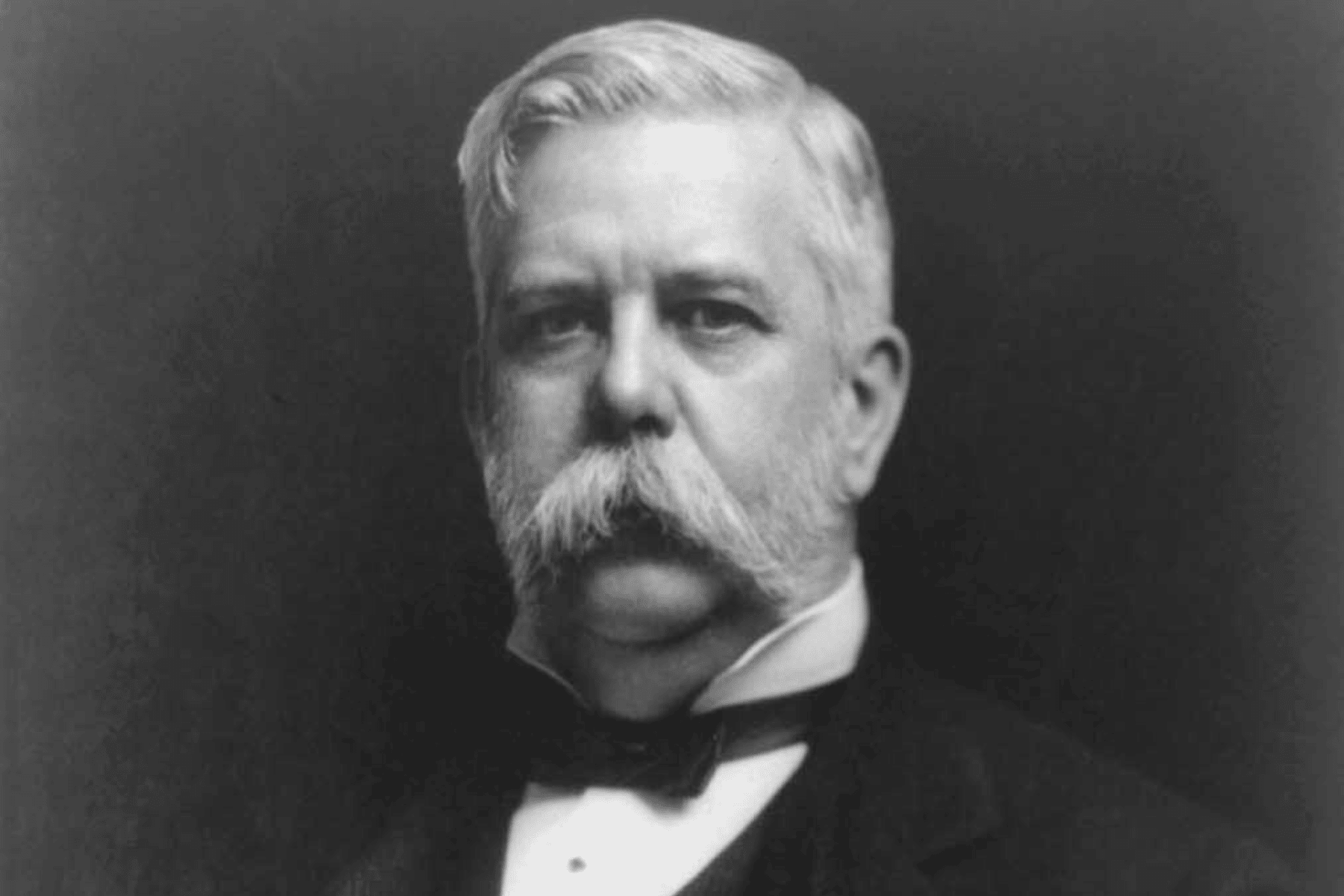

George Westinghouse is an American inventor and industrialist, is widely considered one of the most important figures in the history of brake technology, particularly in the rail industry. He is best known for his invention of the air brake, which revolutionized the rail industry in the late 19th century.

Before Westinghouse’s invention, trains used a variety of mechanical brakes that were operated by hand, which were often unreliable and difficult to use. Westinghouse’s air brake, on the other hand, was operated by compressed air and allowed for more precise and consistent braking. This made trains much safer and more efficient to operate, as the air brake allowed for quicker stopping times and more reliable braking.

Westinghouse’s air brake invention was patented in 1869 and quickly adopted by railroads worldwide. His invention also inspired other inventors to develop air brake systems for other forms of transportation like automobiles, buses, and trucks. This made travel safer and more efficient for all transportation, not just trains. Westinghouse, in my eyes, is an individual worthy of a spot on the Mt. Rushmore of Brakes.

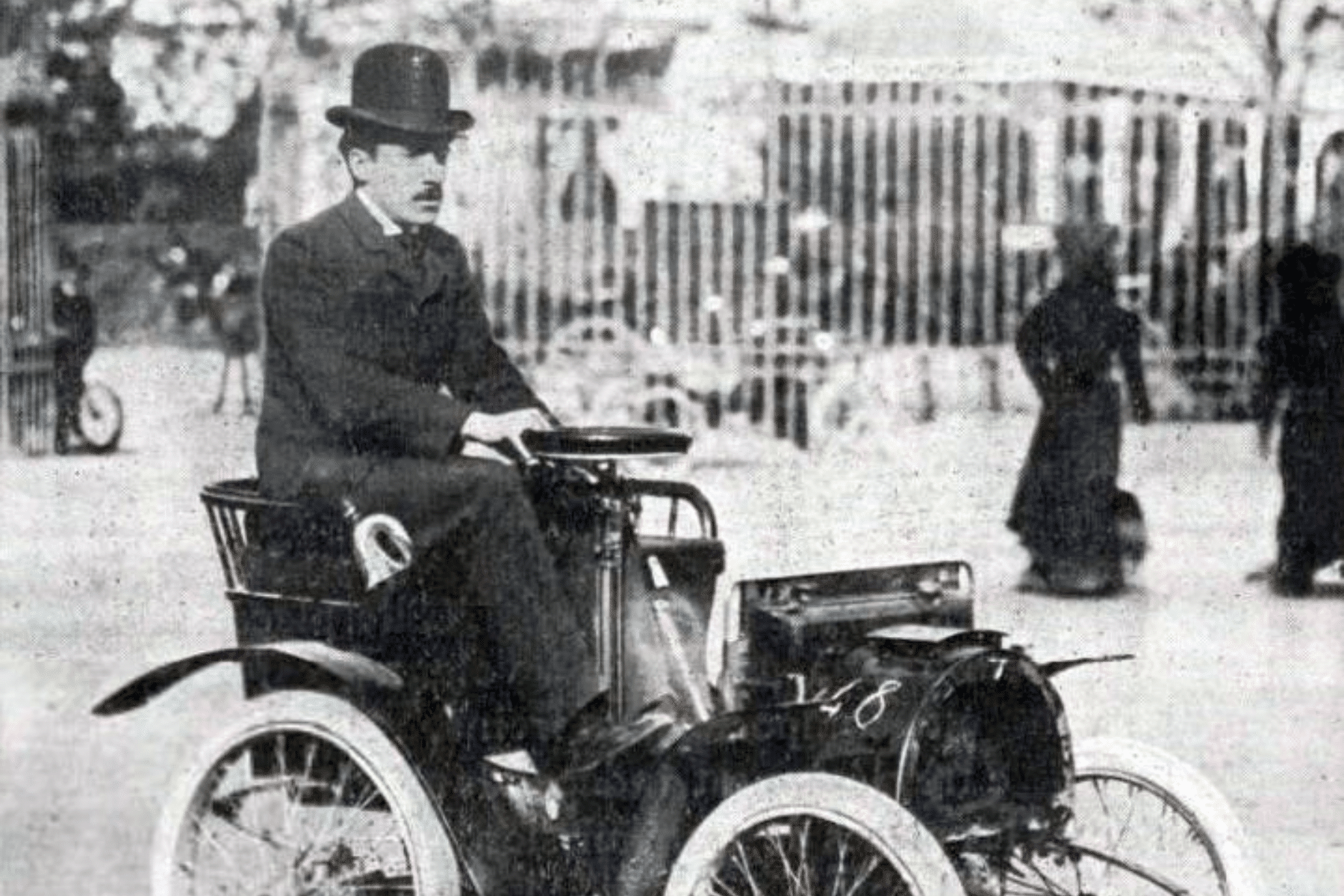

Next, we have Louis Renault. Renault was a French engineer and industrialist who founded the Renault car company. He was one of the first to understand the importance of brakes in automobiles and made significant contributions to the development of brake technology.

One of Renault’s key contributions to the brake industry was his development of the drum brake. Drum brakes are a type of brake that uses friction pads to press against the inside of a drum in order to slow or stop a vehicle. Renault’s design was an improvement over previous drum brake designs and made them more reliable and efficient.

Renault also made other contributions to brake technology, such as the development of the “four-wheel” brake system, where all four wheels of a vehicle have independent braking, rather than just the rear wheels. This made braking more efficient and improved the overall safety of the vehicles.

Third we have the invention of the disc brake by Frederick W. Lanchester in 1902. This was an important milestone in the development of brake technology, but it took several decades before the technology was widely adopted in the automotive industry. The first known use of disc brakes on a production vehicle was by the British car manufacturer, Jensen Motors, in 1953, but it wasn’t until the 1960s that disc brakes began to be widely adopted by the industry.

The duo of Norman Dewis and Sir Stirling Moss, who were test drivers and engineers working for the British car manufacturer, Jaguar, played an important role in popularizing disc brakes and making them a standard option for cars. They helped refine and reintroduce the disc brake as a standard option for cars while working for Jaguar in the 1950s.

Dewis and Moss worked to improve the disc brake design and performance, and their work helped to demonstrate the benefits of disc brakes over drum brakes. Dewis and Moss were instrumental in helping Jaguar to develop the first disc brakes that were reliable enough for high-performance sports cars. They also put disc brakes to the test by setting speed records with them, which helped to demonstrate their superiority over drum brakes.

The impact of disc brakes in the brake industry is undeniable. The efforts of Lanchester, Dewis, and Moss, helped to improve the disc brake design and performance and their work has been instrumental in the widespread acceptance of disc brakes in the automotive industry.

Can we add company names on the Mt. Rushmore of Brakes?

Bosch is a German multinational engineering and technology company that has had a significant impact on the brake industry, particularly in the area of Anti-lock braking systems (ABS). ABS is a safety feature in modern cars that prevents the wheels from locking up during hard braking, allowing the driver to maintain steering control and avoid skidding.

Bosch was the first company to introduce ABS technology in 1978, and it has been credited with reducing the number of accidents caused by braking-related skids. Bosch’s ABS system uses sensors at each wheel to monitor the rotational speed of the wheels. If one wheel is about to lock up, the system reduces the brake pressure to that wheel, allowing it to continue rotating and helping the driver maintain control of the vehicle.

Bosch’s ABS technology was initially developed for use in commercial vehicles, but it quickly found its way into passenger cars as well. The company has continued to innovate and improve its ABS technology over the years, and it is now a standard feature in most modern cars.

In addition to ABS, Bosch has also made significant contributions to the development of other brake technologies such as the electronic stability control (ESC), brake assist systems, and brake-by-wire systems. These technologies have helped to improve the safety and performance of vehicles and have become standard features in modern cars.

Another worthy candidate could be Brembo. Brembo S.p.A. is an Italian manufacturer of automotive brake systems, particularly systems for high-performance cars and motorcycles. The company was founded in 1961 by Emilio Bombassei and Italo Breda in Bergamo, Italy.

Brembo’s brake systems are used by many high-performance car manufacturers, including Ferrari, Lamborghini, and Porsche. In addition to automotive brake systems, the company also manufactures brake systems for motorcycles.

The company’s brake systems use a variety of technologies, including carbon ceramic discs and calipers, which offer increased performance and durability compared to traditional brake systems. Brembo’s brake systems are also used in motorsports, including Formula One and MotoGP.

In recent years, the company has expanded into the electric and autonomous vehicle market, with the development of brake-by-wire systems and other advanced technologies. It also established a partnership with the major player in the electric car industry, Tesla, to develop and produce braking systems for its vehicles.

Akebono is a global leader in the design, development, and production of advanced brake and friction products. The company’s history can be traced back to 1929, when it was founded as a small brake pad manufacturer in Japan.

Throughout the decades, Akebono has continually invested in research and development to improve the performance and safety of its products. In the 1950s, the company introduced asbestos-free brake pads, which were safer and more environmentally friendly than traditional asbestos-based pads. In the 1970s, Akebono developed ceramic brake pads, which offered superior performance and durability compared to traditional semi-metallic pads.

In the 1980s, Akebono expanded its product line to include brake calipers and rotors, and began exporting its products to other countries. This expansion helped the company establish a global presence and become one of the largest brake manufacturers in the world.

In the 1990s and 2000s, Akebono continued to innovate and improve its products. It introduced ceramic composite brake pads, which offered even better performance and durability than traditional ceramic pads. The company also developed brake systems for electric and hybrid vehicles, recognizing the growing demand for these types of vehicles in the global market.

Today, Akebono continues to be a leading provider of advanced brake and friction products, with a strong focus on safety, performance, and environmental sustainability. Its products are used by leading automakers around the world, and the company has facilities and partnerships in several countries. As the world is moving towards electric vehicles and sustainable transportation, Akebono is working towards to be a key player in the industry.

A recent innovation worth mentioning

Let’s add a Canadian brake company to the list, Eh? NUCAP Industries is a global innovation company headquartered in Toronto. Since 1994, NUCAP has been a leader in brake safety, having developed braking solutions with the world’s top brands in more than 90 countries.

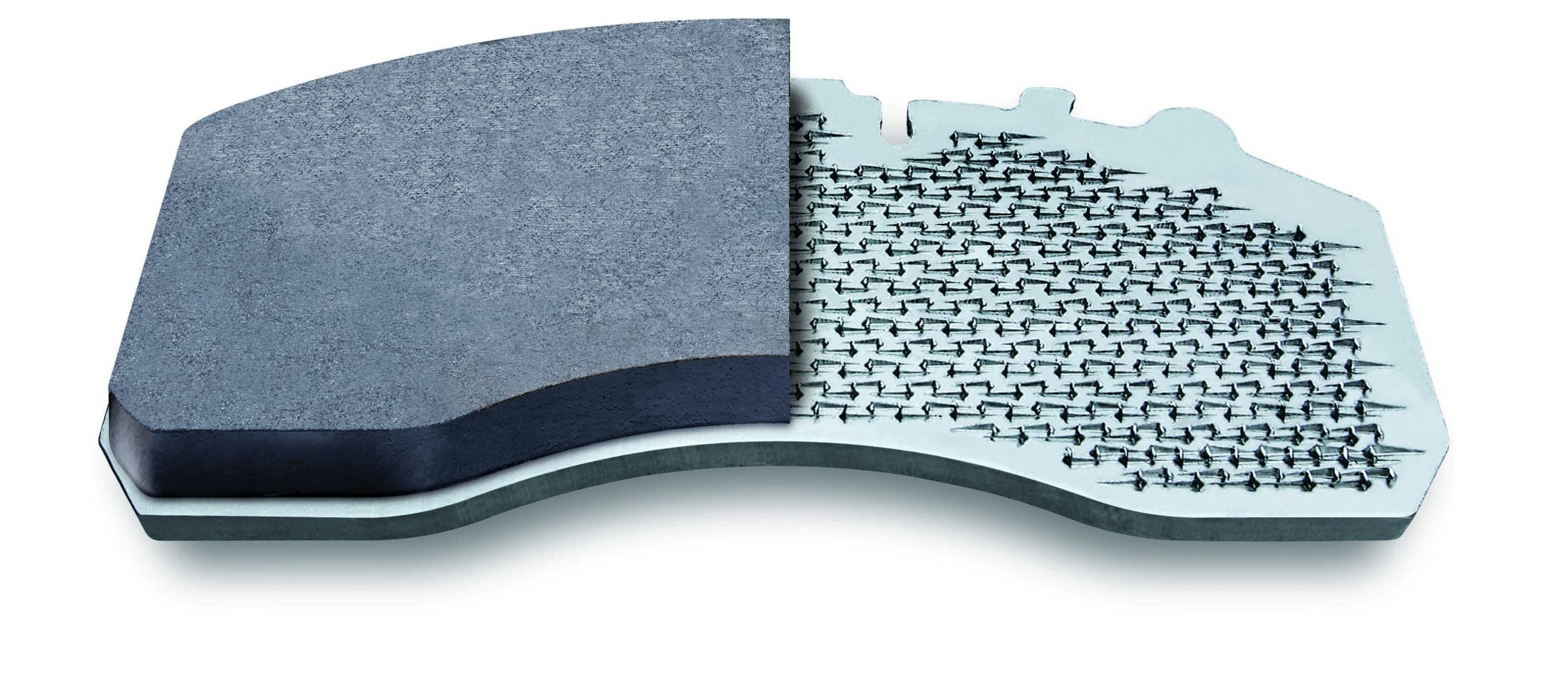

NUCAP revolutionized the brake market by developing and introducing NUCAP Retention System. This technology is a revolutionary new design for brake pads that improves their overall performance and longevity. This technology uses a unique micro-metallic compound to bond the brake pad’s friction material to the metal backing plate. This creates a strong, durable connection between the two parts, which helps to reduce the risk of brake pad delamination.

One of the major advantages of the NUCAP retention system is its ability to improve the overall performance of brake pads. This is because the micro-metallic compound used in the retention system allows for a more consistent friction material transfer to the rotor, improving braking power and responsiveness. Additionally, the retention system helps to prevent the formation of hot spots on the rotor, which can lead to uneven wear and reduced braking performance.

Another benefit of the NUCAP retention system technology is its ability to extend the lifespan of brake pads. This is because the retention system helps to prevent delamination, which can cause brake pads to wear out prematurely. Additionally, the retention system also helps reduce the amount of debris generated during braking, which can further extend the life of the brake pads.

The NUCAP retention system technology is a significant advancement in brake pad design, and offers many benefits over traditional brake pad systems. With improved performance and longevity, this technology can provide drivers with a safer and more reliable braking experience.